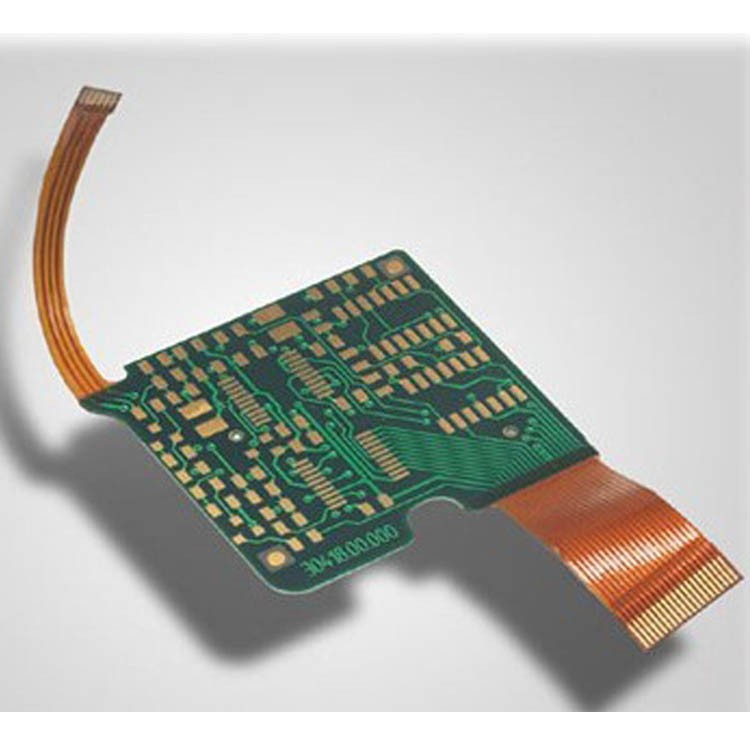

How to bend the PCB?

The advanced bent PCB is a multilayer composite wiring board, which laminates a printed wiring board (PWB) and a flexible PCB (FPC) in a multilayer structure. PWB and FPC have copper plated through holes to connect to each other. The circuit board is most suitable for use in small and light equipment.

Features

(1) The new models with the following specifications can be used as the best solution for mobile phones.

·Minimum base thickness: 0.3mm (4 layers), 0.39mm (6 layers)

·Minimum line width/interval: 0.075mm/0.075mm

·Flexibility of single-sided or double-sided flexible PCB (FPC) (as a folding sheet): radius of 3mm, 180° folding, can be folded more than 200,000 times.

(2) It can be connected without contact and at a small pitch, and the equipment can be assembled very compactly in a three-dimensional space.

(3) In the multi-layer (3-8 layers) part, plated through holes are used to realize the connection between the board and the board, thus greatly enhancing the reliability.

(4) The ease of assembly is equivalent to that of a normal printed wiring board.

(5)

A "chip on hole" (chip on hole) specification is available, so that a "blind via hole" (Blind via Holes) can be used as a chip pad.

Overall specifications

Type Foldable type Flying line type

Minimum thickness of substrate*1 0.54mm [4 layers], 0.61mm [6 layers], 0.9mm [8 layers]

Minimum line width/spacing 0.1/0.1mm

Minimum through hole diameter φ0.2mm

The smallest through hole area diameter (through hole) [Outer layer] φ0.5mm,

[Inner layer] φ0.5mm [Outer layer] φ0.5mm,

[Inner layer] φ0.65mm

The smallest through hole area diameter (blind through hole) [Outer layer] φ0.5mm, [Inner layer] φ0.5mm

Minimum diameter of through hole area (built-in through hole) [Inner layer] φ0.5mm

Welding strength Multi-layer: liquid optical solder mask, FPC: film coating

Surface finishing, thermal resistance pre-coated flux, nickel-gold coating, (nickel-gold coating for flying leads)

Safety standard (UL certification) (94V-0)

The structure of advanced bending PCB (6 layers as an example)

Flexible composite multilayer PCB (flexible and robust specifications)

The advanced bent PCB is a multilayer composite wiring board, which laminates a printed wiring board (PWB) and a flexible PCB (FPC) in a multilayer structure. PWB and FPC have copper plated through holes to connect to each other. The circuit board is most suitable for use in small and light equipment.

Features

(1) Multiple pressed layers are internally connected with a flexible PCB (FPC), thus improving the reliability of the connection between the multilayer circuit boards, and reducing the space occupied by the connection and the weight of the joint.

(2) Achieved a narrow interval (0.5mm) of CSP and bare chip mounting, thereby achieving ultra-high-density mounting and making the device more compact and exquisite.

(3) Realization of "internal connection and through-hole connection" and structural lamination, so an ultra-high-density wiring design can be obtained.

(The design provides more free space to make the product smaller and thinner.)

Overall specifications

Type F1 (5th to 8th floors)

Number of layers Hard core layer 1 per side

Floor

Core layer structure 3~6 layers (polyimide, FR-4)

Minimum board thickness 0.8mm (6 layers), 0.87mm (8 layers)

Through hole diameter, round hole diameter Conformal through hole φ0.15mm/φ0.35mm

Stacked through holes ー

Recessed built-in through hole available

Built-in through hole diameter φ0.2mm

Minimum line width/spacing *2 0.09mm/0.09mm

CSP can be installed pitch 0.8mm

Safety standard 94V-0 (waiting for UL certification)

Composite multilayer PCB

Composite multi-layer PCBs can be installed with 0.5mm pitch CSPs, thus reducing the size and thickness of PCBs, enabling high-density mounting design.

Features

(1) Small pitch (0.5mm) CSP ICs and bare chips can be installed in ultra-high density.

(2) Recessed through holes and stacked through structures can realize ultra-fine wiring design.

Overall specifications

Type R1 (4~10 floors)

R2 (6-10 floors)

Number of layers Hard core layer 1 per side

Layer Hard core layer 2 per side

Floor

Core layer structure 2-8 layers (FR-4, FR-5) 2-6 layers (FR-4, FR-5)

The minimum thickness of the board is 0.48mm, (6 layers)

0.6mm, (8 layers) 0.56mm, (6 layers)

0.62mm, (8 layers)

Through hole diameter, round hole diameter Conformal through hole φ0.15mm/φ0.35mm φ0.13mm/φ0.275mm

Laminated through hole ー φ0.15mm/φ0.35mm

Recessed built-in through hole available

Built-in through hole diameter φ0.2mm

Minimum line width/spacing *2 0.09mm/0.09mm 0.075mm/0.075mm

CSP can install pitch 0.8mm 0.5mm

Safety standard (UL certification) 94V-0

Solid PCB

Sharp's rugged PCB can maintain continuous good performance under long-term and harsh conditions, and is known for its excellent reliability, which can meet the various needs of users.

Features

(1) Comply with various specifications, such as SMT/COB/fine mode/multilayer PCB.

(2) From CAD design to circuit board completion, all operations are performed under a fully streamlined command monitoring system.

(3) Flexible PCB and rugged PCB can be combined into Rigid-Flex Board.

Overall specifications

parameter

Overall specifications

Design pattern width

4 floors 6 floors 8 floors

Minimum total thickness 0.35mm 0.45mm 0.6mm

Design pattern width: inner layer: 0.1mm, outer layer: 0.1mm, (partial: 0.075mm)

Design pattern spacing Inner layer: 0.1mm, Outer layer: 0.1mm

Types of through holes Whole through hole, BVH (chip on hole), IVH

Through hole area diameter φ0.2mm (finished)

Finishing processing (surface) thermal resistance pre-coating flux, nickel-gold coating, tin leveling agent

series

Multilayer PCB Double-sided PCB/Others

●Micro-hole PCB ●Low heat dissipation rate ●Micro-hole PCB

●Chip-on-hole PCB

(Chip can be installed)

●Low inductance PCB ●Anti-leakage PCB

●Halogen free

Flexible PCB

Flexible PCB is designed to improve space utilization and product design flexibility, which can meet the needs of smaller

And higher density HDI PCB mounting design needs. It also helps reduce assembly processes and enhance reliability.

Features

(1) High-density mounting circuits, SMT and other most suitable flexible PCBs can be provided.

(2) High-precision type and other electronic connectors installation types for COF with flip chip mounting and circuit bonding capabilities can be provided.

Standard

Number of layers single side

Double-sided through hole

Backing material Polyimide film, adhesive-free polyimide

Design pattern width 0.02 mm (MIN.) 0.05 mm (MIN.)

Design pattern spacing 0.04 mm (MIN.) 0.05 mm (MIN.)

Through hole/land diameter - φ0.1 mm/φ0.3 mm (MIN.)

Covering layer Polyimide film, thermal insulation coating, liquid solder mask

★Series

Multilayer flexible PCB Double-sided flexible PCB

Single layer flexible PCB

Rigid bending PCB

Single-sided high-precision flexible PCB Double-sided high-precision flexible PCB

※other series

Bonded nickel gold coating

Highly flexible type (bending ability)

High density SMT

Contact us if you need more details on Flex Pcb Coverlay. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flex Pcb Cable、Flex Pcb Electronique. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Rigid-Flex Board > Flexible Pcb